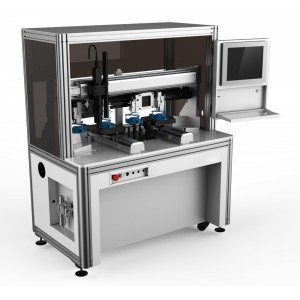

Tabber Stringer For 156-230 MBB Silicon Wafer

Type:

Specification:

Profile:

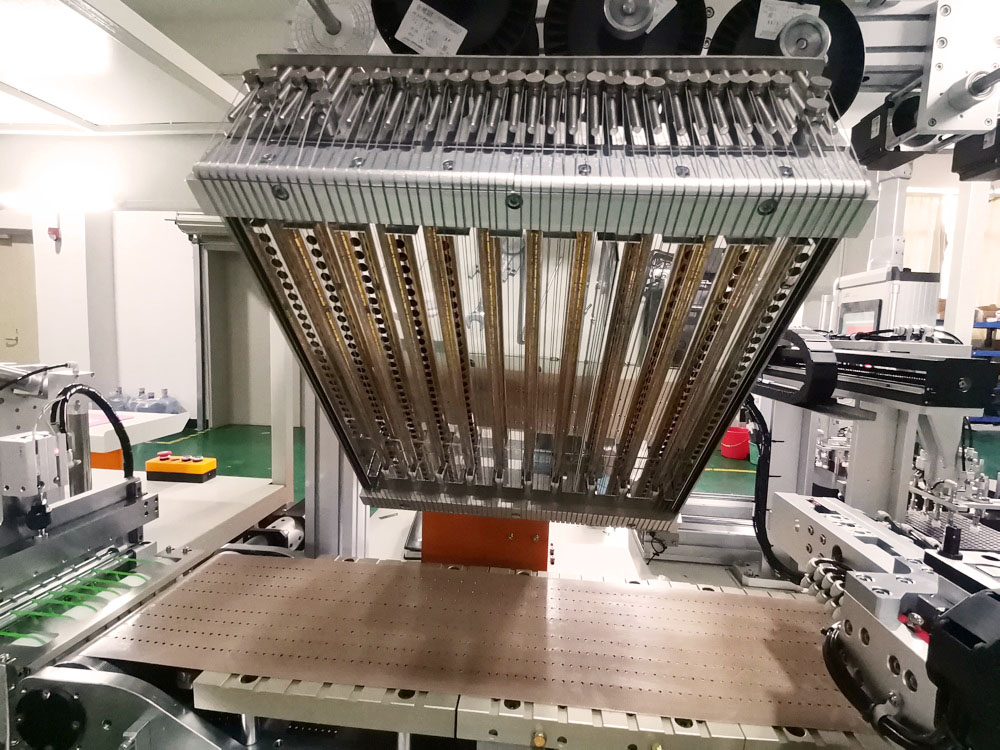

Tabber stringer is used to weld solar cells to strings; stringer machine OCH2020 with camera for cell detection before soldering, speed is 1800PCS/hour.

Tabber Stringer For 156-230 MBB Silicon Wafer

Machine Function

Tabber stringer is used to weld solar cells to strings; stringer machine OCH2020 with camera for cell detection before soldering. Optical mechanical ribbon positioning to ensure more accurate alignment. Speed is 1800 PCS/hour.

Technical Parameter

|

No. |

Item |

Specification |

Remarks |

|

1 |

Soldering capacity |

Max 2 seconds/pcs, Max 1800 pcs/hour |

|

|

2 |

Cell size |

30~156x156mm 30~166x166mm |

|

|

3 |

Cell busbar |

156mm 3BB/4BB/5BB/6BB 166mm 6BB/9BB |

|

|

4 |

Cell thickness |

≥160 micron |

|

|

5 |

Ribbon size |

Width:0.9~2.0mm Thickness:0.15~0.23mm |

Ribbon size should be informed by customer before order |

|

6 |

Breakage rate |

≤0.2% |

On the basis of Grade A cells |

|

7 |

Ribbon alignment tolerance |

≤0.3mm |

External dimension and printing show no difference |

|

8 |

Cell spacing |

1~20mm |

The maximum spacing of 156mm complete cells is 5mm |

|

9 |

Cell basket capacity |

4 x 100 PCS |

4 cell baskets to load maximum 100pcs each, total 400 pcs, auto switch |

|

10 |

Soldering technology |

IR light |

|

|

12 |

Soldering temperature |

Normal~400℃(adjustable) |

|

|

13 |

Input power |

Three~phase/50~60Hz/380V/30A |

Power cable>6 mm² |

|

14 |

Peak power |

20KW |

|

|

15 |

Average power |

6KW |

|

|

16 |

Compressed air |

≥0.6MPa dry & clean air |

|

|

17 |

Compressed air consumption |

Approx 200 liter/min |

|

|

18 |

Max. String Length |

2050mm |

Suitable for 12pcs 6inch cells per string with 2mm cell spacing |

|

19 |

Operation Method |

PLC touch-screen |

|

|

20 |

Operator Interface |

Chinese and English |

|

|

21 |

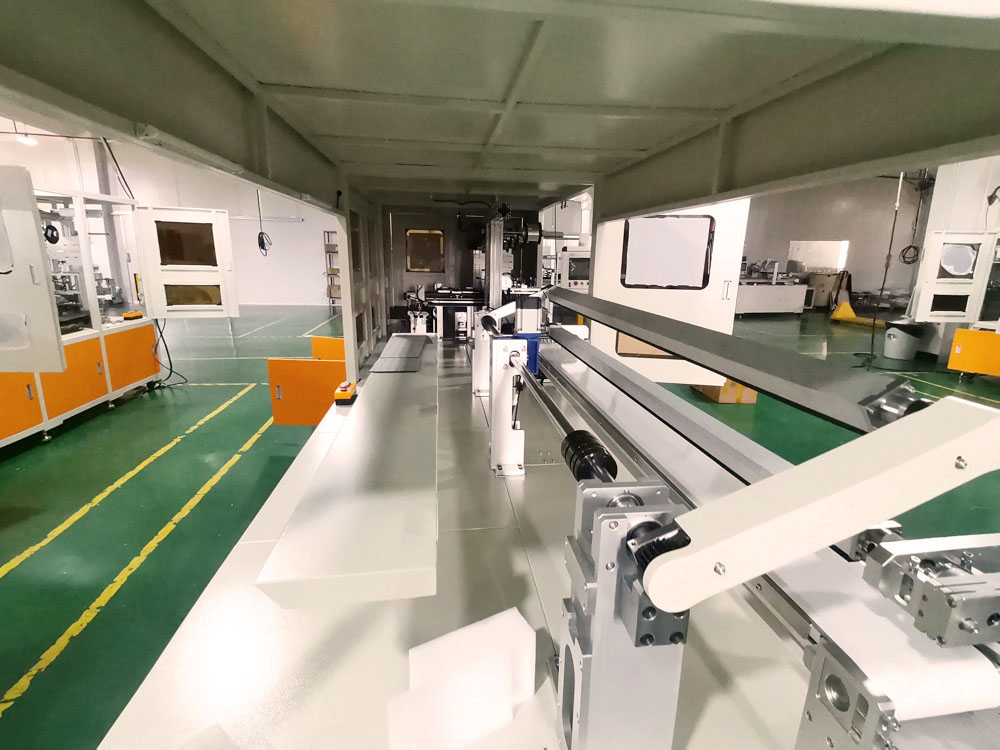

Dimension |

5390mmx1560mmx1950mm |

Length*width*height(warning light size excluded) |

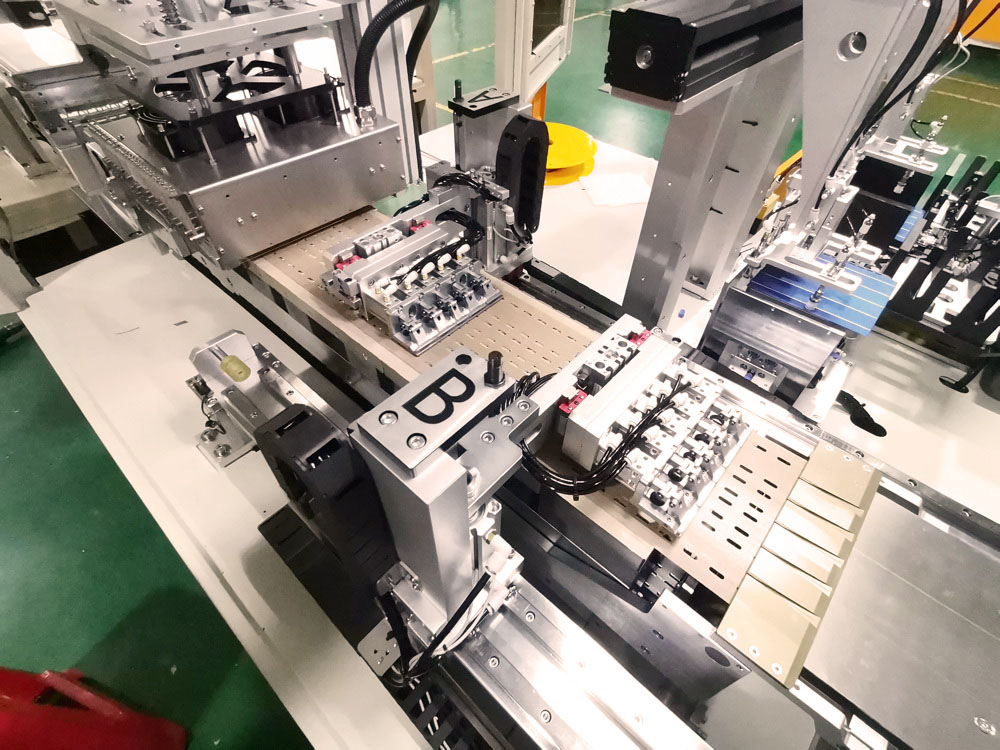

Detail picture

About US

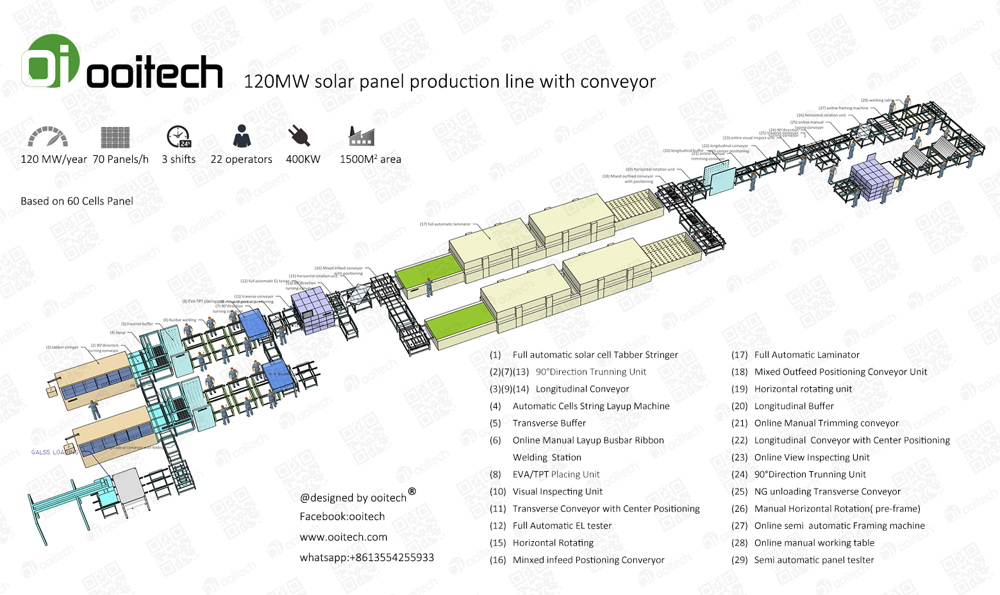

Ooitech, One-stop Solution For Solar Panel Manufacturing Equipment.

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assitance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Supply 10MW-500MW PV Manufacturing Machine

Update the traditional PV line to newest MBB solar panel production line.

Main machinery

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

High Speed Automatic Layup Station

Solar Cell Laser Cutting Machine

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

High Speed Automatic Layup Station

Solar Cell Laser Cutting Machine

Customers who bought this product also purchased: