Full Automatic Solar Panel Production

Type:

Specification:

Profile:

Full Automatic Solar Panel Production Including the following products:

· Solar Cell Tester

· Damage Free Solar Cell Laser Cutting Machine

· Solar Cell Stringer Machine

· Cell String Lay Up Machine

· String Ribbon Soldering Machine

· Solar Modul

How To Make Full Automatic Solar Panel Production?

Many customers want to make solar panel production, but they don’t know how to configure production line and equipment, so that the project has been delayed to start.

So, What Machines are Included in Full Automatic Solar Panel Production?

Full Automatic Solar Panel Production Including the following products:

· Solar Cell Tester

· Damage Free Solar Cell Laser Cutting Machine

· Cell String Lay Up Machine

· String Ribbon Soldering Machine

· Solar Module EL Defect Tester with Visual Inspecting Function

· Laminator Machine

· Aluminum Framing Machine

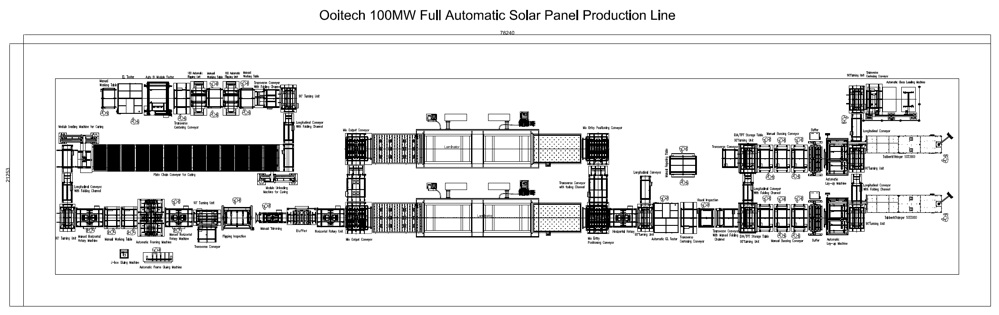

1. Factory Layout Drawing:

2. Function & Picture of Main Machines of Full Automatic Solar Panel Production:

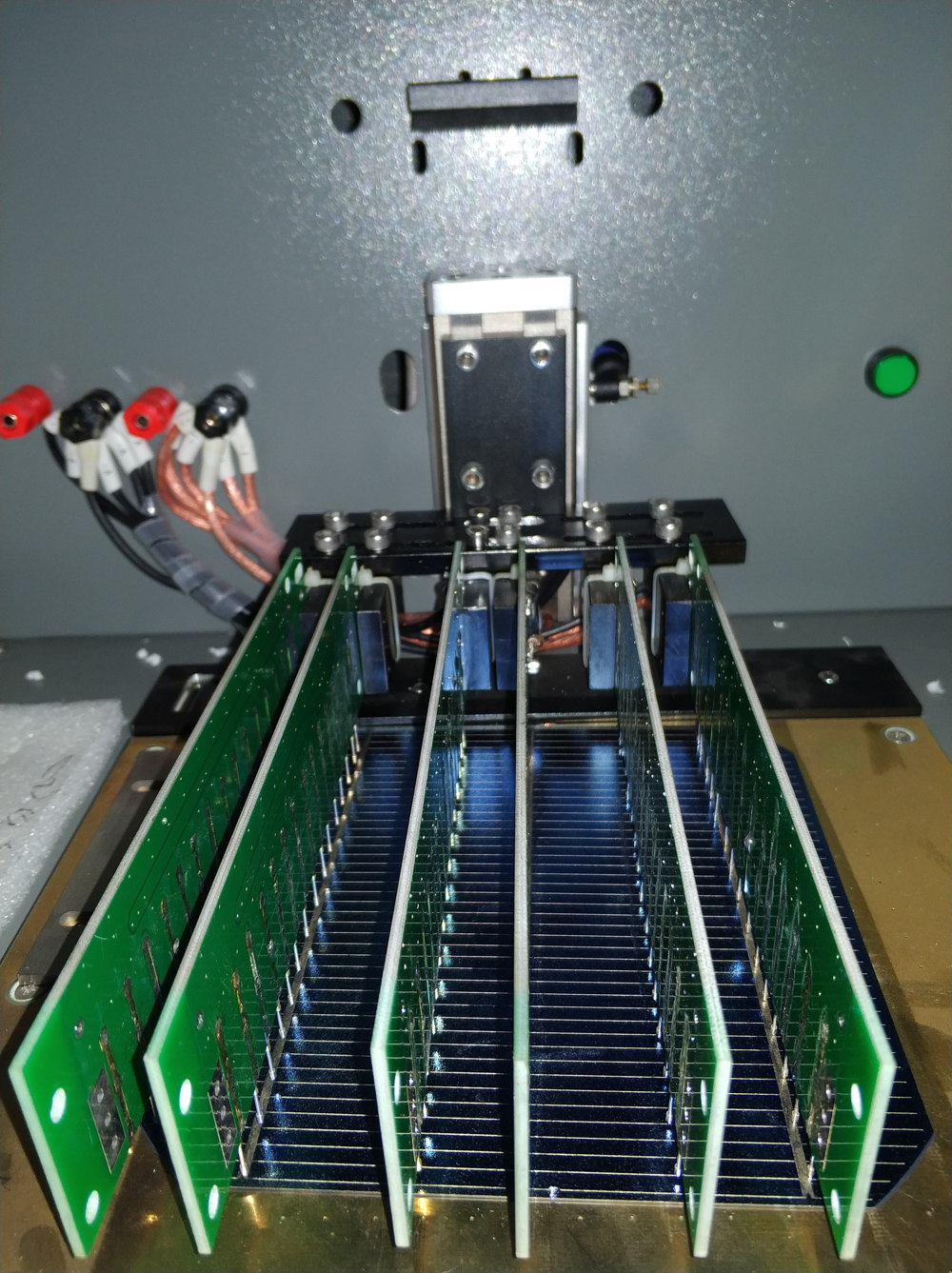

· Solar Cell Tester

Function:

Use to test the electrical performance of Mono-Si or Poly-Si solar cell pieces and record the results in files.

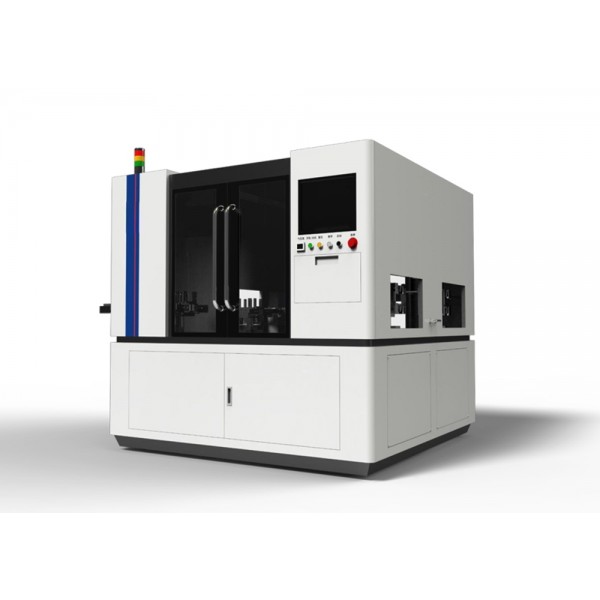

Picture:

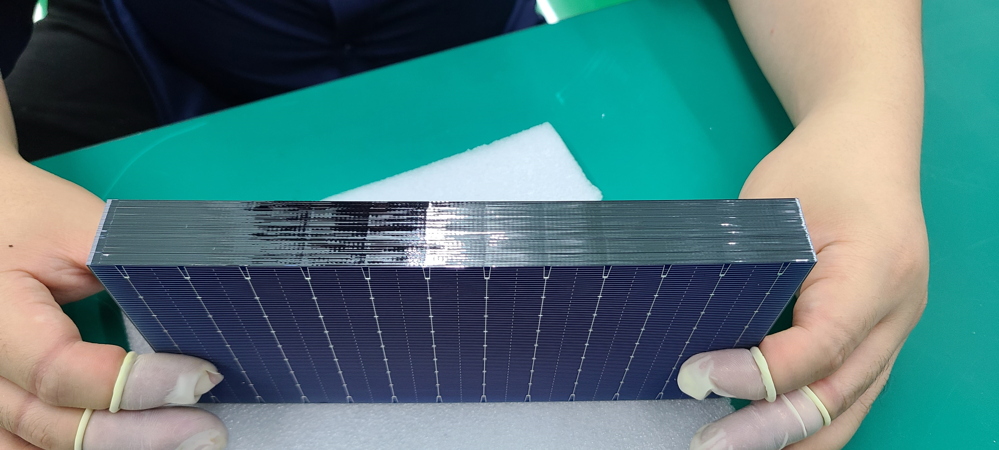

· Damage Free Solar Cell Laser Cutting Machine

Function:

No water no destructive solar cell laser cutting machine (called NDC) cuts solar cell into half piece or 1/3 piece,which can increase the output of the solar panel power.

NDC is with lower power, lower temperature, and water-free dicing, and also has higher bending strength, better electrical performance, and no secondary pollution or water-caused micro-broken after cutting.

Picture:

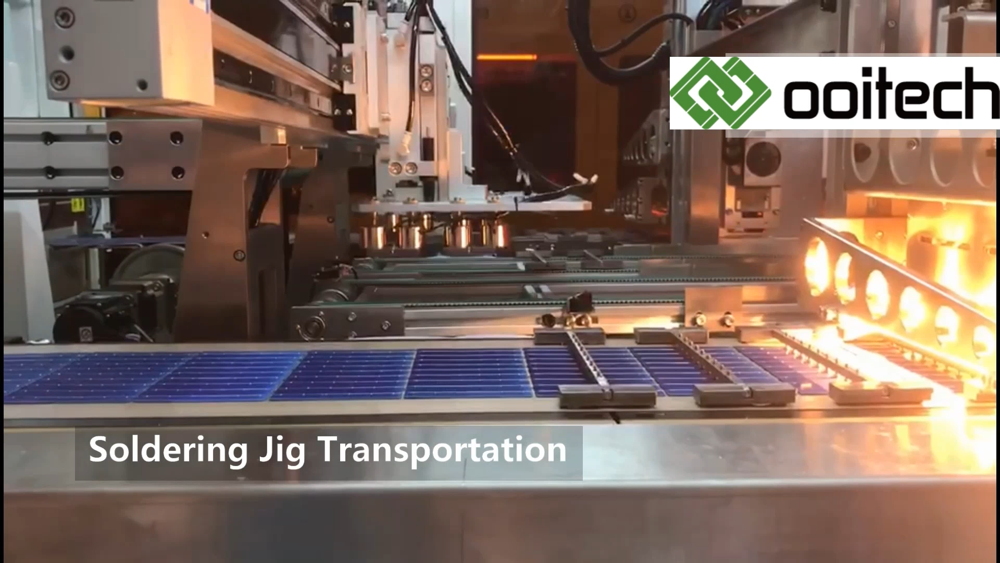

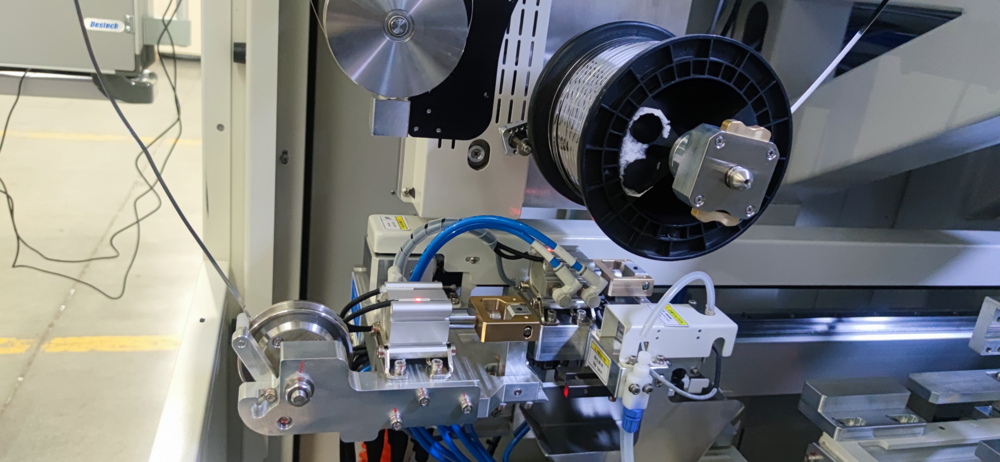

Function:

Automatic stringer is to weld the solar cells one by one through copper ribbon, and the cells are connected in series to form a string. The entire welding process is fully automated.

Picture:

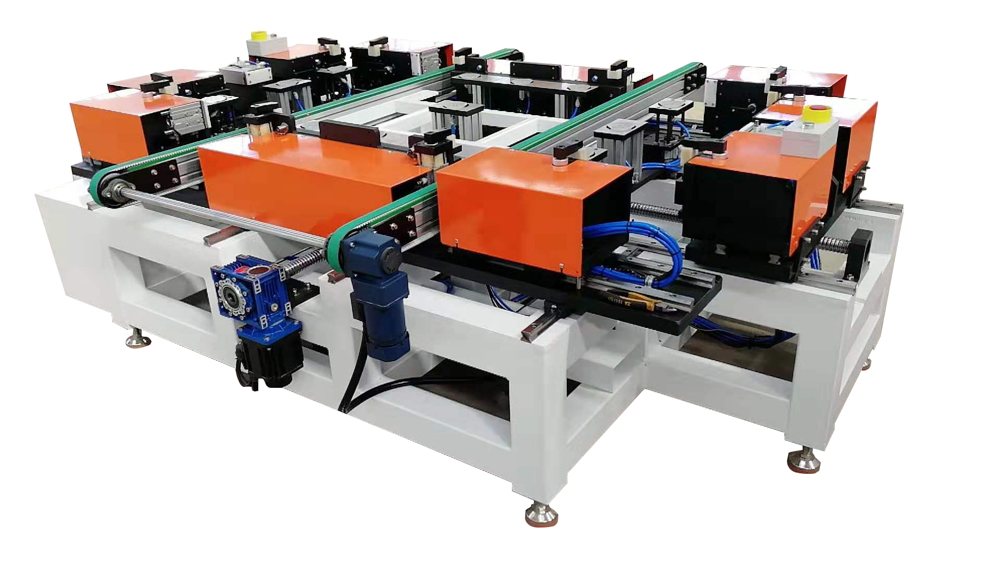

· Cell String Lay Up Machine

Function:

Achieving solar string automatic laying on glass EVA, and transporting module to the next process

Picture:

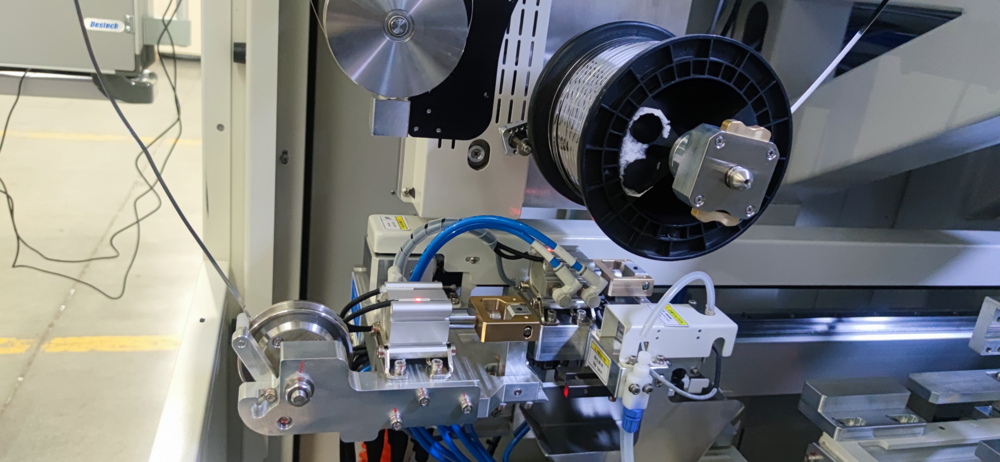

· String Ribbon Soldering Machine

Function:

Adopt the method of separating the cell string from the glass, and grab the cell string in the air, then to interconnected solder the head, middle and tail bus bar of the middle wire edition module at a certain height; It has the function of a roll feeding bus bar, bending U and L leads upwards.

Picture:

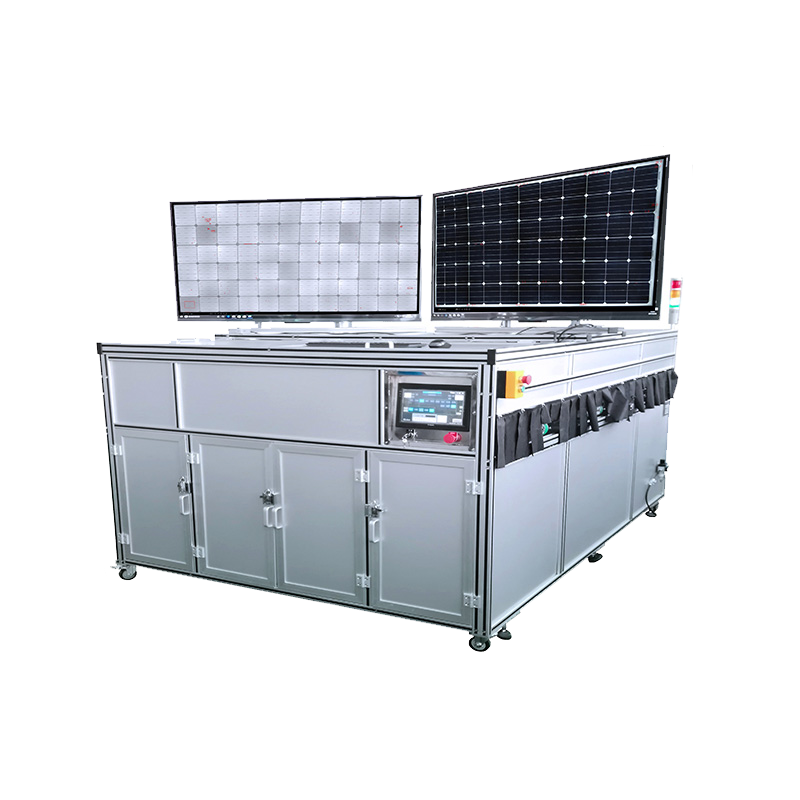

· Solar Module EL Defect Tester with Visual Inspecting Function

Function:

Used in testing the solar cell crack,breakage, black spot,mixed wafers,process defect,cold solder joint phenomenon.

Picture:

· Laminator Machine

Function:

Solar panel laminator is a mechanical device that presses multiple layers of materials together.

Picture:

· Aluminum Framing Machine

Function:

Automatic gluing & framing machine is used to install the aluminum frame and automatically overflow glue.

Picture:

· Sun Solar Simulator

Function:

Automatic solar panel IV tester is used to test the electric performance of Mono-Si or Poly-Si solar modules and record the results in files .

Picture:

3. Packaging and transportation of Full Automatic Solar Panel Production:

4. Case of Full Automatic Solar Panel Production:

Customers who bought this product also purchased: