5BB-20BB PERC TOPCon HJT Solar Cell Welding Stringer

Type:

Specification:

Profile:

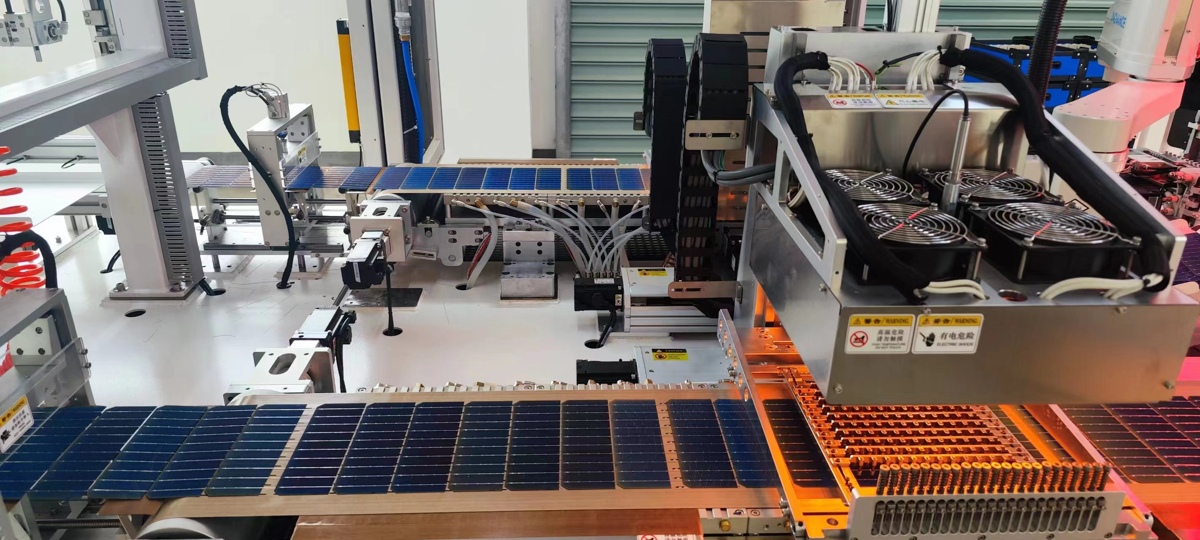

5BB-20BB PERC TOPCon HJT Solar Cell Welding Stringer is suitable for soldering crystalline silicon solar cells into a string.

This machine can support 20BB.

Customers can choose to customize all white or blue and white.

5BB-20BB PERC TOPCon HJT Solar Cell Welding Stringer

Machine Function

Solar cell welding stringer is suitable for

soldering crystalline silicon solar cells into a string.

This machine can support

20BB.

Customers can choose to customize all white or blue and white.

Equipment Advance

l Qualified soldering effect, which approves soldering pulling testing higher than 1N/mm on cell surface (0.6*0.25mm ribbon, 180 degree pulling angle, and except HJT cell)

l Exchange time less than 120mins for changing different bus-bar number(9BB&12BB), including 30-60mins for changing tools and 30-60mins for tuning and calibrating. Exchange time less than 30mins for different cell sizes (whole cell, half-cell, third cell and quarter cell) while bus-bar number fixed.

l Ribbon extruding in advance before soldering.

l Pre-heating before soldering to avoid cell deformation efficiently

l Touchable integrated PC system can support remote assistance, we can provide online technical support for after-sales issues.

l Can be integrated with other Solar equipment conveniently.

l Remote assistance by Internet, the factory provides the network connection.

l No pre-heating required for Ribbon before soldering.

l No specialized engineer required for maintenance, but engineers must be trained and qualified.

l Solar cell soldering numbers per string can be set by PC.

Technical Parameter

|

Product model |

SS-2500 |

|

Product capacity |

≥2400cell/hour |

|

Breakage Rate |

≤0.2%(A grade cells) |

|

Cell size available |

156-210mm*1/4-1/2 |

|

Cell inspection |

CCD camera detection (Busbar/missing corner) |

|

Bus Bar QTY Available |

3BB-20BB |

|

Cell thickness |

0.16-0.25mm |

|

Ribbon available |

Flat ribbon, width: 0.35-1.2mm; thickness: 0.15-0.25mm |

|

Soldering method |

IR heating soldering |

|

Flux coating method |

Soak of ribbon |

|

Soldering head |

2pcs |

|

Number of Cell Cassette |

5PCS,250PCS/cassette |

|

Equipment failure rate |

≤4% |

|

Time for changing Jigs |

≤40Min(average) |

|

Cell spacing |

1.5-10mm(depend on the cell size) |

|

Max string length |

2000mm |

|

Positioning method |

CCD camera+ Robot positioning |

|

Robot positioning accuracy |

±0.02mm |

|

Electrical system |

PLC+ touch screen+servo+module+robot |

|

Human-machine interface |

Touch screen display,friendly interface for easy operation. |

|

Fault alarm |

Real time fault alarm |

|

Device noise |

<80db |

|

Power supply |

Three-phase five-wire,380VAC/50Hz |

|

Rated power |

20KW |

|

Air source |

6-8Bar:800L/min;Inlet pipe diameter:16mm |

|

Device dimension |

8200mm*1900mm*2300mm Working platform height: 900mm±25mm |

|

Weight |

4500Kg |

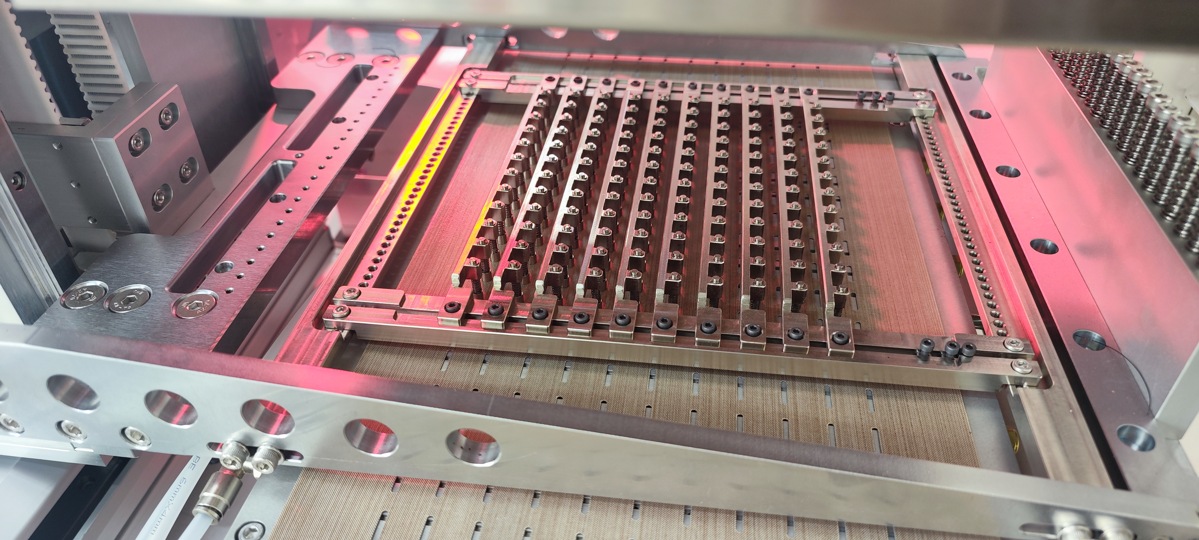

Detail picture

About US

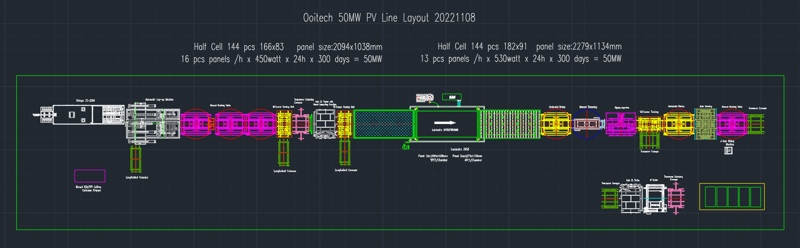

Ooitech, One-stop Solution For Solar Panel Making Machine.

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Supply 10MW-500MW Solar Panel Making Machine

Update the traditional PV line to newest MBB solar panel production line.

Main machinery

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

High Speed Automatic Layup Station

Customers who bought this product also purchased:

Online Automatic Solar Module EL Defect Tester with Visual Inspecting Function

Online Automatic Solar Module EL Defect Tester with Visual Inspecting Function Automatic Solar Panel Gluing and Framing Machine

Automatic Solar Panel Gluing and Framing Machine Flexible Automatic Shingled Stringer for Customizable Solar Panel Manufacturing

Flexible Automatic Shingled Stringer for Customizable Solar Panel Manufacturing Efficient Shingled Solar Cell Terminal Head Welding Machine for lmproved Solar Panel Manufacturing

Efficient Shingled Solar Cell Terminal Head Welding Machine for lmproved Solar Panel Manufacturing