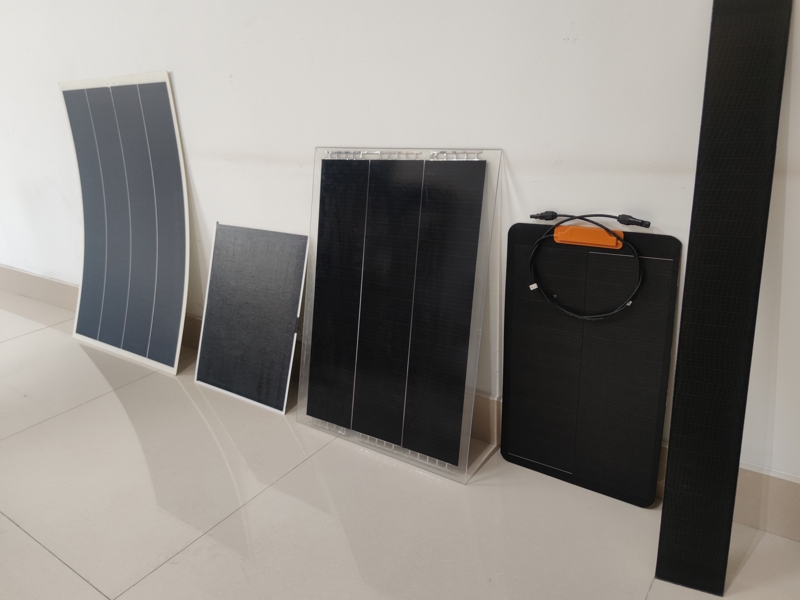

Flexible Automatic Shingled Stringer for Customizable Solar Panel Manufacturing

Type:

Specification:

Profile:

Shingled stringer is an automatic equipment to weld the solar cells into strings by curing the conductive adhesive and collect the welded strings (or transfer them directly to the later process). The equipment adopts various advanced automation technologi

Flexible Automatic Shingled Stringer for Customizable Solar Panel Manufacturing

Machine Function

Automatic shingled stringer is an automatic equipment to weld the solar cells into strings by curing the conductive adhesive and collect the welded strings (or transfer them directly to the later process). The equipment adopts various advanced automation technologies such as PLC, linear module, servo motor, dispensing system, curing unit, and discharging mechanism to achieve fully automatic processing from cell loading to string discharging.

Technical Parameter

Product Model

SL-30C

Production capacity

3000≥PCS/H(1/5,1/6,1/7*210mm)

5000≥PCS/H(1/5,1/6*26-78mm)

Overlapping accuracy

±0. 15mm

Cell inspection

CCD camera detection (Busbar/missing corner/hidden

crack)

Maximum operation speed

1000mm/s Adjustable

Spraying method

Spray coating; glue width 0. 251-mm adjustable;

glue application volume adjustable

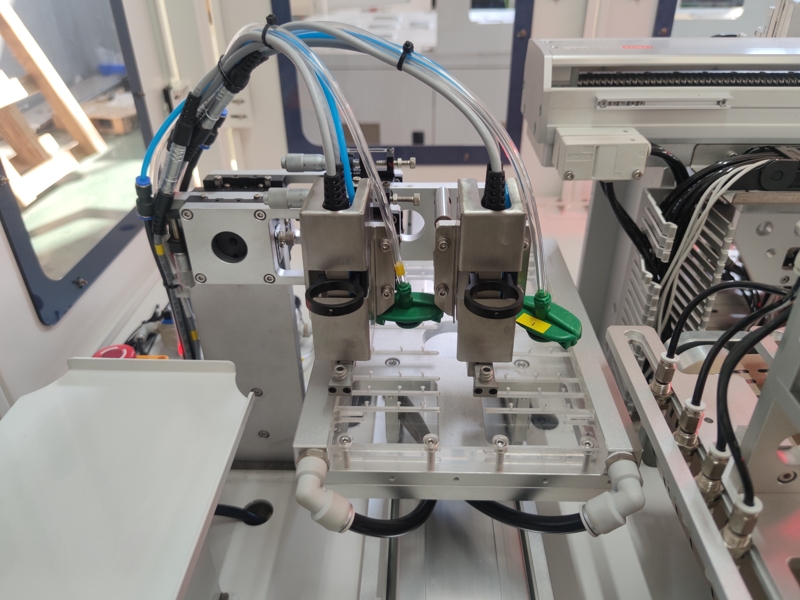

Number of glue heads

2 pcs

Number of basket

3 pcs; 250 pcs/basket.

Feeding method

Rotary loading; non-stop for feeding basket.

Cell defect rate

≤0. 2% ( A grade cells)

Equipment failure rate

≤3%

Cell overlap volume

1-10mm Adjustable

Curing method

High temperature curing (PID temperature control system, Temperatures in the 6 zones

are adjustable, real-time temperature monitoring

(Real-time monitoring)

Positioning method

Mechanical positioning

Electrical system

PLC+touch screen+servo+module

Human-machine Interface

Touch screen display, friendly interface for easy

operation

Fault Alarm

Real-time fault alarms

Device color

Main body traffic white + sky blue

Power supply

Three-phase five-wire, 380VAC/Hz50

Rated power

4KW

Air Source

68-Bar; 600L/min ; Inlet pipe diameter: 12mm

Equipment size

L*W*H 4790*1250*1876mm(without alarm light)

Weight

1400Kg

Software

Lifetime free upgrades

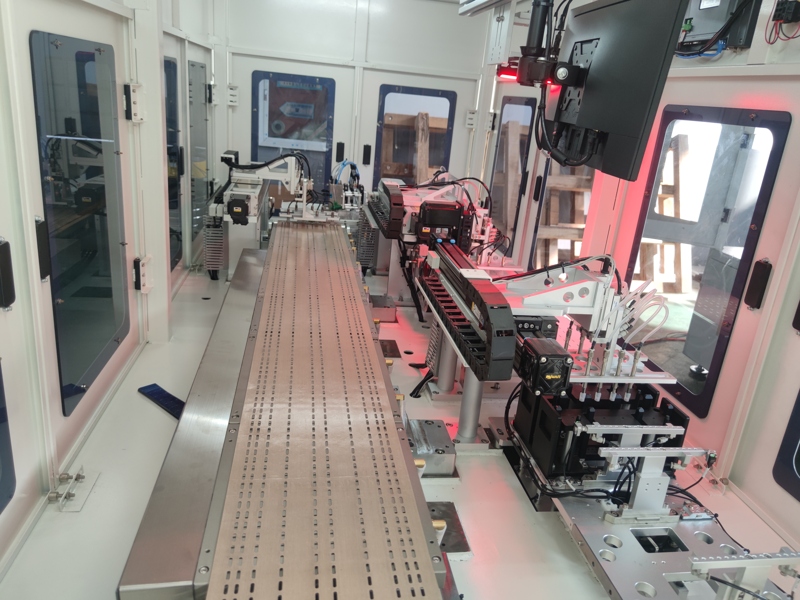

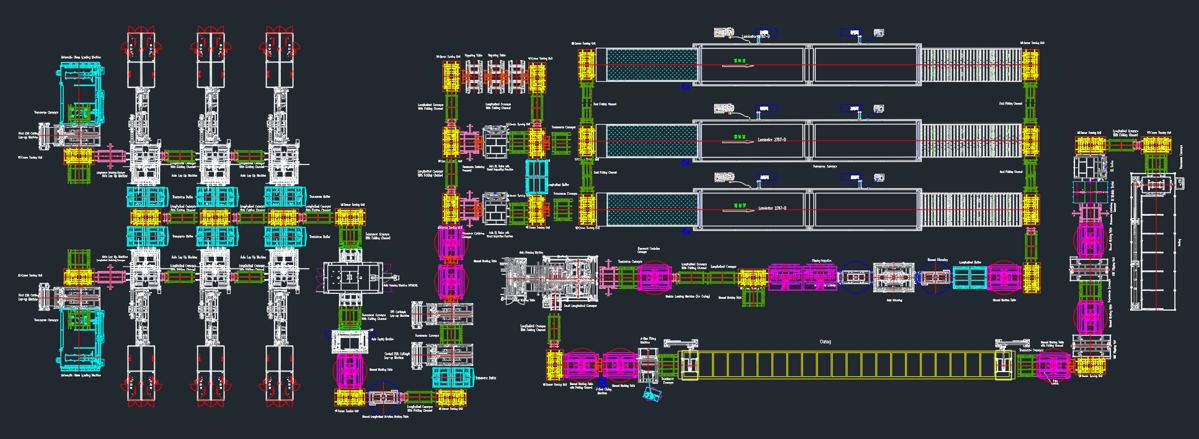

Detail picture

About US

Ooitech, One-stop solution for solar module making machine. Has the following required machinery and accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Supply 10MW-500MW Solar Module Making Machine

Update the traditional PV line to newest MBB solar panel production line.

Main machinery

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

High Speed Automatic Layup Station

Customers who bought this product also purchased:

5BB-20BB PERC TOPCon HJT Solar Cell Welding Stringer

5BB-20BB PERC TOPCon HJT Solar Cell Welding Stringer Online Automatic Solar Module EL Defect Tester with Visual Inspecting Function

Online Automatic Solar Module EL Defect Tester with Visual Inspecting Function Efficient Shingled Solar Cell Terminal Head Welding Machine for lmproved Solar Panel Manufacturing

Efficient Shingled Solar Cell Terminal Head Welding Machine for lmproved Solar Panel Manufacturing Boost Your Solar Panel Production with MBB PV Cell Soldering Stringer - Advanced Technology for Streamlined Manufacturing Processes

Boost Your Solar Panel Production with MBB PV Cell Soldering Stringer - Advanced Technology for Streamlined Manufacturing Processes